The installation design of photovoltaic brackets: How to take into account reliability and cost and benefit, and achieve a win -win situation?

Imagine that when the sun is full of earth, we can not only feel its warmth, but also transform it into a steady stream of green energy. This is the magic of photovoltaic power generation! However, behind this magnificent blueprint, there is a vital link that is often ignored -the installation design of photovoltaic brackets. It is like the "bone" of the power station, supporting the stability and efficient operation of the entire system. How to maximize cost benefits while ensuring reliability? This is not only a technical challenge, but also a test of wisdom.

1. Careful selection: seeking the perfect combination of performance and economy

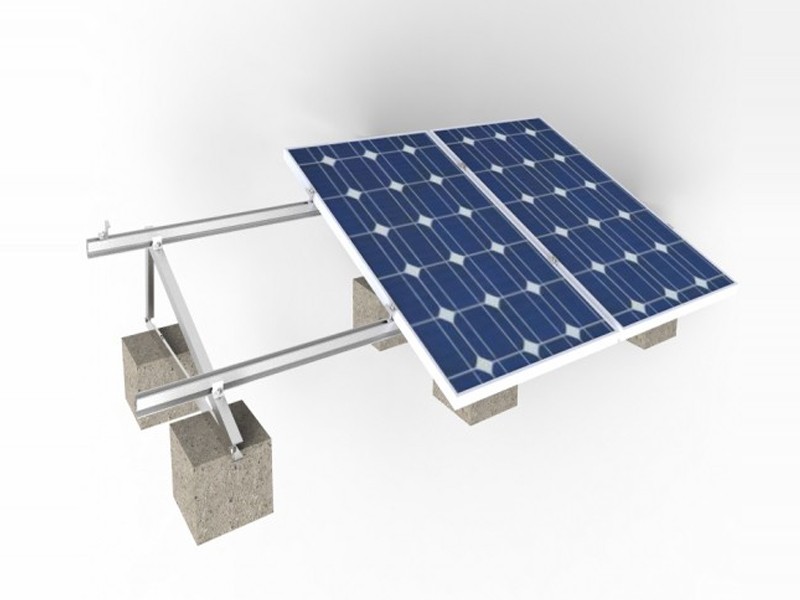

When selecting the bracket, we need to comprehensively consider multiple factors. The first is material selection. Common bracket materials include aluminum alloy, galvanized steel and stainless steel. They each have advantages and disadvantages. Aluminum alloy brackets are light and corrosion -resistant, suitable for most environments; galvanized steel brackets have higher strength and stability, suitable for harsh environments such as wind and snow. Secondly, the structure type is also the key to selection, including fixed, adjustable and tracking. The cost of fixed brackets is relatively low, suitable for areas with stable sunshine conditions; adjustable brackets can adjust the angle of adjustment according to seasonal changes to improve power generation efficiency; while tracking brackets can track the solar location in real time and maximize the use of sunshine resources. Considering performance and economy, we can choose the most suitable bracket type for power stations.

Second, clever layout: Optimize space configuration and improve power generation efficiency

The layout plan is very important for the power generation efficiency of photovoltaic power stations. During the planning stage, we need to make full use of the terrain and landforms and sunshine conditions, and to adjust the inclination, spacing and arrangement methods of the bracket to achieve efficient use of land and space. For example, in mountains or hills, we can flexibly adjust the height and angle of the bracket according to the terrain changes to ensure that each photovoltaic board can obtain sufficient sunlight; in the plain area, we can reduce shadow cover by optimizing the arrangement of the bracket to reduce shadow cover. , Improve the efficiency of overall power generation. In addition, we also need to consider the operation and maintenance needs of the power plant to leave enough space between the brackets to facilitate cleaning, maintenance and replacement in the future.

Third, rigorous construction: detailed achievement excellent quality

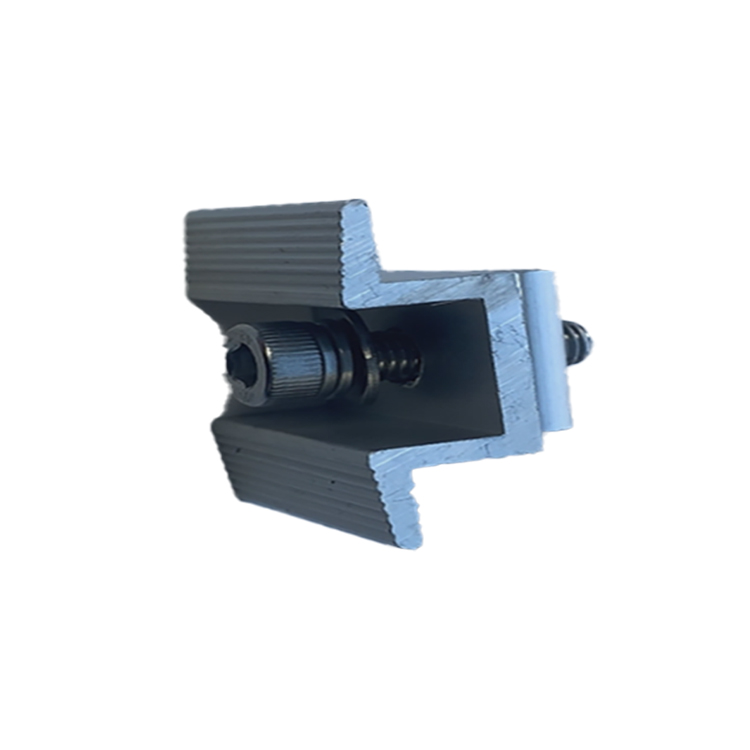

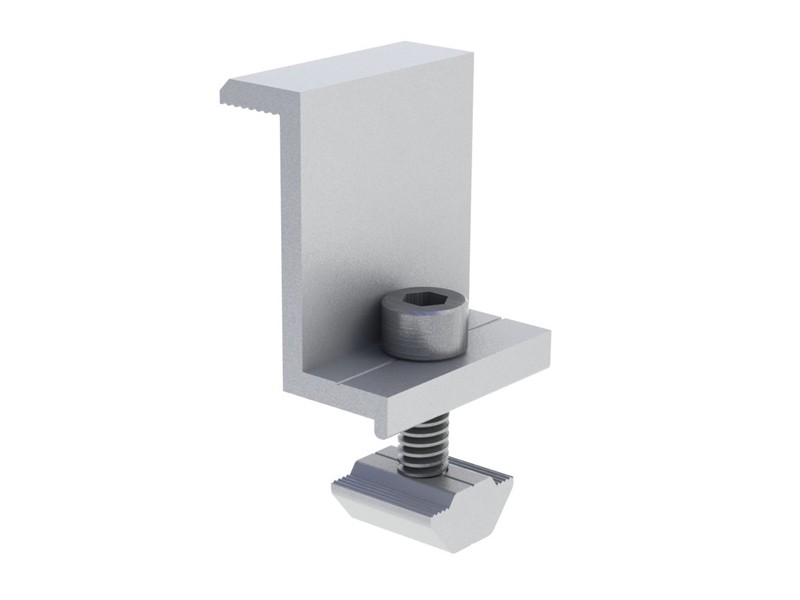

The installation of photovoltaic brackets has a decisive impact on the safety and power generation efficiency of the power station. During the construction process, we must work strictly in accordance with the design drawings and operation specifications to ensure that the installation location, angle and height of each stand are accurate. At the same time, we also need to pay attention to construction details, such as the connection between the bracket and the foundation, the fixation of the bracket and the photovoltaic board, etc., all need to use high -quality connectors and fasteners to ensure that the connection is firm and reliable. In addition, in the construction process, we also need to do a good job of safety protection to provide the construction staff with the necessary safety training and protection measures to ensure the safe and smooth progress of the construction process.

Fourth, smart cost control: maximize economic benefits

Cost control is one of the key links in the construction of photovoltaic power stations. For photovoltaic brackets, cost control involves multiple aspects such as material procurement, processing, production, and transportation installation. In the initial cost budget of the project, we need to comprehensively consider various factors, including material prices, processing costs, transportation costs, and installation costs. Through clever negotiations and comparisons with suppliers, we can reduce procurement costs; by optimizing production technology and improving production efficiency, we can reduce processing costs; through reasonable arrangements for transportation plans and selecting economic and efficient transportation methods, we can reduce transportation costs ; By improving installation efficiency and reducing the waste of labor costs, we can reduce the cost of installation. These wisdom cost control measures will help us maximize economic benefits.

V. Innovation driver: Lead the photovoltaic bracket industry to a new height

Technological innovation is one of the important drivers to promote the sustainable development of the photovoltaic bracket industry. With the continuous progress of technology and the continuous emergence of new materials, we have the opportunity to further improve the performance and reliability of photovoltaic brackets through innovative design. For example, we can explore the use of new high -intensity composite materials to manufacture brackets to achieve lighter weight, higher strength and better corrosion resistance; we can also introduce intelligent monitoring and control systems to monitor the power station in real time monitoring power stations The operating status is optimized; in addition, the modular design concept is also a direction worth exploring. By disassembling the stent into multiple standard modules for combination, it can improve installation efficiency and convenience. These technological innovation will help us lead the photovoltaic bracket industry to a new height and achieve a wider range of applications.